Serve manufacturers all over the world

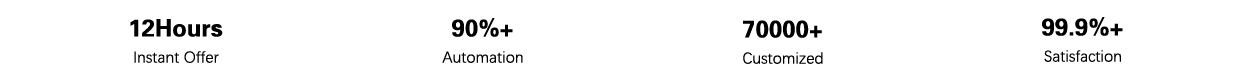

CangzhouWeizhi was established in 1999 and is a metal processing customization company that provides one-stop services for global customers. Currently, it has 120 employees, including designers and engineers, production personnel, welders, machine operators, quality inspectors, R&D personnel, and customer service staff, among whom 19 are engineers.

Our factory is located in Nanpi County, the hometown of hardware manufacturing. It not only has a standardized factory covering an area of over 9,000 square meters, but also holds ISO 9001:2015 international quality management system certification.

We have the complete process capability to transform your requirements into physical products precisely!