Cangzhou Weizhi was founded in 1999. Since its establishment, it has been devoted to the custom metal parts industry. The company has a factory covering over 9,000 square meters and can reliably handle a wide range of customized orders. Our staff total 120, among whom 19 are engineers. At present, we have customized over 70,000 parts for more than 3,000 enterprises across over 100 countries.

Our Technology Can Almost Customize All Metal Products!

We Have Rich Experience in Metal Bending Services

To date, we have cooperated with over 3,000 enterprises from more than 100 countries and have customized and processed over 70,000 types of metal parts for them.

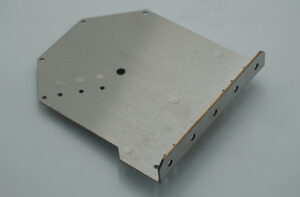

The Product Coverage Is Extremely Wide

The parts we have customized cover a range of industries, including industrial equipment, automobiles, aerospace, medical care, and construction. Regarding metal bending services, our core capabilities include complex surface forming, high-precision Angle control, and processing of difficult-to-machine materials.

Have Experience in High-Demand Customization

We have supplied belt conveyor idler brackets and bucket frame brackets for bucket elevators to conveying equipment manufacturers. These brackets are formed by cold bending at a bending speed of 2-5m/min, and the rebound angle must be controlled to ≤2°. The Angle deviation (±0.5°) was measured with a three-coordinate measuring instrument, and the surface was galvanized for anti-corrosion protection.

Unique Small and Medium-Sized Order Service

Using rapid prototyping equipment, we can go from design drawing to sample production in as little as 8 hours. Based on this, we have formed a dedicated team to handle small- and medium-sized orders and sample requests, providing these customers with fast, efficient service.

Why Can We Serve Over 3,000 Enterprises Worldwide

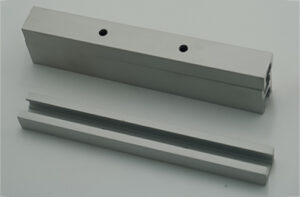

The Most Advanced Equipment

Relying on years of continuous investment in equipment construction, we now have three sets of bending machines of different sizes and advanced equipment covering the entire process, including 40 stamping machines, two sets of 6-kilowatt laser cutting machines, two five-axis CNC machining centers, and three vertical CNC machining centers. With the strength of this equipment, we can efficiently integrate core processes such as stamping, laser cutting, CNC machining, casting, welding, and bending, and flexibly meet your needs from prototype to mass production.

A Company with International Quality Management System Certification

Relying on ISO 9001:2015 international quality management system certification, we provide customers with stable, reliable quality assurance, ensuring that products meet the highest industry standards in terms of quality and performance.

Efficient Production Process

We understand the importance of completing the project on time. Our simplified processes and advanced equipment enable us to achieve 24/7 Automated Production, with a daily output exceeding 50,000 pieces. We can supply stably at any time and strictly adhere to delivery dates, providing a solid guarantee for customer demands.

Price Competitiveness

We always adhere to the bottom line of quality and, on that basis, offer you more competitive pricing that balances quality and cost. All quotations are transparent and detailed, allowing you to understand the cost details at a glance.

Professional full-process service support

Our experienced foreign trade and business team offers full-process follow-up services. We can provide detailed quotations within 8 hours and ensure a comprehensive customer experience.

Nothing Found

Sorry, but nothing matched your criteria. Perhaps searching can help.

Copyright © 2026 respond All Rights Reserved.

cangzhou weizhi

ISO 9001-2015 Certified