How do We Achieve Precision Metal Fabrication Through Advanced Equipment

Since its establishment in 1999, we have grown from a single workshop to a modern manufacturing base covering over 9,000 square meters and have passed ISO9001:2015 quality management system certification.We can provide you with precision metal fabrication services.

We are a trusted partner for over 3,000 enterprises worldwide and have customized more than 70,000 different types of parts. Now, please follow us and gain a deep understanding of the core strength of our personalized services, delivered with genuine parts and equipment.

From Flat Sheets to Complex Components: Precision Sheet Metal Fabrication

Our sheet metal processing services cover the entire process, from cutting and forming to joining. Provide efficient production solutions for chassis, brackets, and shells.

PS: To learn more about the parts we have made, click here.

Cutting and stamping: We are equipped with 40 sets of 60-400-ton stamping machines and two sets of 6-kilowatt laser cutting machines. It integrates high-precision planar cutting and efficient three-dimensional forming capabilities.

Forming and joining: Through pipe bending/folding equipment, an automatic spot welding system, and three electric welding lines. Simultaneously ensure the accuracy of complex bending and the strength and appearance of the connection points.

High-Precision Core – CNC Machining Center

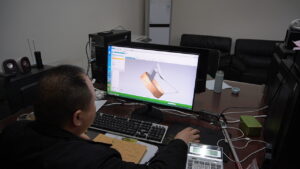

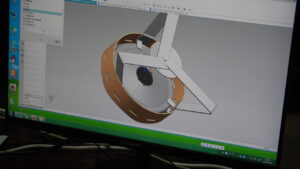

Our CNC machining centers are the key to ensuring part accuracy. This area is home to our most sophisticated equipment, specializing in handling high-precision hole systems and irregular-shaped parts.

Five-axis machining centers (2 units): They are used for five-sided processing of complex parts (such as impellers and molds) and can be completed in a single clamping.

Vertical machining centers (3 units): Suitable for batch processing, including milling, drilling, and tapping of plate, disc, and shell parts.

PS: Click here to view the parts we have made.

Perfect Appearance and Protection – Surface Treatment and Marking

The life of metal parts lies not only in their strength and precision, but also in their durability and the permanence of their marking. Our surface treatment and marking capabilities provide a solid guarantee for this.

Surface treatment: 2 fully automatic production lines, covering processes such as phosphating, electroplating, anodizing, powder coating, sandblasting, and wire drawing.

Product marking: 4 laser marking machines, supporting the engraving of permanent serial numbers, QR codes, logos, and text on various materials.

Solid Foundation – Metal Casting

We can also provide complete metal casting solutions. We work closely with our customers to select the most suitable processes and materials for manufacturing wear- and high-temperature-resistant components.

The Eye of Quality: Whole Process Inspection and Control

Digital precision measurement: We have two coordinate measuring machines (CMM). They can perform non-contact high-precision scanning and comparison on complex workpieces.

Total quality management: Quality inspection runs through every link, from raw material inspection and first production inspection to process patrol and final factory inspection, forming a complete quality closed loop.

Beyond Equipment – Our Intellectual Capital

The company has over 120 employees, and its core technical team consists of 19 engineers with more than 20 years of experience. We can provide you with free project optimization services covering materials, processes, costs, and post-processing.

Precision Collaboration – Starting From Samples and Ending With Service

We offer free samples and promise to be accompanied throughout the process by a professional team. Accurately match demands before sales, ensure progress and delivery dates during sales, and provide rapid responses after sales.The picture below shows our sample display cabinet.

Your Ideal Manufacturing Partner

Over 9,000 square meters of space, equipment, technology, and human resources work efficiently together to transform a monthly production capacity of over 50,000 pieces into your market competitiveness.Click here to learn more about how we can help your project succeed.

With 25 years of accumulation, we are ready to provide you with comprehensive manufacturing solutions to safeguard your project.