The chassis processing and manufacturing engineer is by your side, not just a supplier

In the world of equipment manufacturing, a chassis is never merely a shell. We focus on chassis processing and play the role of an extension of your team – starting from the first stroke of the drawing, we will work with you to refine, simulate, and optimize it until it is perfectly manufactured. This is what we define as “the chassis manufacturing engineer by your side”.

We are your partners in the product team

1.Starting from collaborative analysis, lay the foundation for outstanding chassis processing

When the project starts, we will proactively initiate a “Design Outpost Meeting”. We not only record the requirements but also use engineering thinking to help sort them out.

Scene diagnosis: In what kind of real environment will your device operate? (For example: hot aisles in data centers, vibrating environments in factory workshops, exposure to sun and rain on outdoor equipment?).”

Contradiction Trade-off: How to find the best balance point between heat dissipation efficiency and EMC shielding, structural strength, and lightweight.

Full life-cycle consideration: Is there room for future upgrades? How long is the maintenance window period, and how can the cover be opened and inspected as quickly as possible?

Case:An industrial automation customer needs to add 30% heating elements in a compact chassis. Through thermal simulation analysis, we proposed a “asymmetric deflector plate + stepped opening” scheme that achieves a 15℃ temperature reduction and a 3 dB noise reduction without changing the external dimensions.

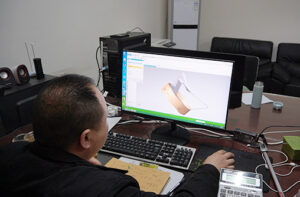

2. Simulation-driven design: Eliminating potential hazards for precision chassis processing

We use tools such as SolidWorks Simulation and ANSYS Fluent to conduct rigorous tests on the “digital prototype”. This enables us to:

Weaknesses of the perspective structure: Simulate chassis vibration and force, and reinforce in advance to avoid on-site resonance.

Optimize the airflow path: Precisely adjust the Angle of the air guide slot and the distribution of openings to eliminate heat-dissipation dead zones.

Perform a tolerance rehearsal: Tolerance superposition analysis to ensure installation consistency between the first and 1000th pieces.

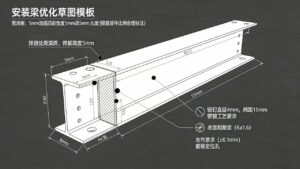

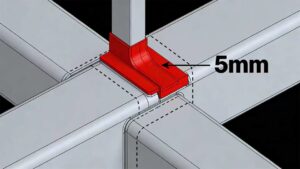

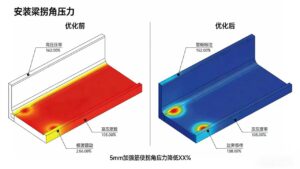

Design Dialogue Case:

Sir, the finite element analysis of the installed beams indicates that the corner stress is relatively high under extreme vibration. It is recommended to add 5mm reinforcing ribs. This is simulated data. This optimization will directly enhance the reliability of the finished products in the subsequent chassis processing. Is it okay? –This is our daily design conversation with you.

3.A chassis processing and manufacturing cluster designed for complex engineering

Our equipment is not an isolated entity but a “craftsman combination” that works in concert to fulfill your design intentions.

Intelligent stamping unit (38 sets, 80-400 tons): Facing the problem of easy cracking of deep drawn parts? In combination with progressive molds, one-time molding is achieved.

High-power laser cutting center (6 kw, ±0.01mm): There are hundreds of irregular-shaped heat dissipation holes on the panel. It ensures that hole positions are free of burrs and deformations and can also automatically optimize the cutting path to save 15% of material.

High-precision bending center: Worried about the straightness of long-sized bending? Through real-time pressure feedback compensation, ensure that the error of the 2-meter-long side plate is less than 0.1mm.

PS: Click to learn about our full range of equipment and see how we can safeguard your project.

4. Quality control ensures that problems do not occur anywhere

We ensure reliability through a three-layer quality inspection system:

The first comprehensive verification: Assemble a complete chassis to simulate installation and wiring, and to preview the design’s rationality.

Process data monitoring: Real-time monitoring of key parameters, and engineer intervention within 5 minutes when the trend deviates.

Functional reproducibility testing: Regularly spot-check finished products and test performance, such as temperature rise and vibration, in a simulated environment.

5. Flexible production and response system

We are well aware that the market waits for no one. To this end, we have established a systematic emergency support capability.

Intelligent scheduling for flexible production lines: Reserve a 20% buffer in capacity. In the event of urgent needs, the intelligent MES system automatically identifies them. It connects directly to the “green channel” production line.

Full-process visual tracking: From material procurement to final quality inspection, customers can view the order status in real time. Master the production dynamics and plan the subsequent work.

8-hour abnormal response closed loop: Set up a dedicated rapid-response line. When there is a problem: assess within 1 hour, develop a solution within 3 hours, implement measures within 8 hours, and update the executable delivery schedule.

Case: A medical equipment customer urgently needed to modify the shell structure. We completed the review, simulation, and processing within 60 hours. We delivered the first batch of 50 qualified samples to ensure the clinical verification cycle.

Added value beyond supply

Cost optimization suggestion: Save 15% of manufacturing costs for customers through process optimization.

Material selection consultation: Recommend the most suitable material based on the environment (such as 304 stainless steel vs galvanized sheet vs aluminum alloy).

Packaging and logistics solutions: Design reusable packaging to reduce the rate of transportation damage.

Technical support: Provide guidance on installation and maintenance for your team.

Continuous improvement feedback: Collect product performance data from actual use and provide iteration suggestions.

PS: Learn more about our mission and team

Industry application cases

Communication industry: High-density signal adapter module chassis, taking into account both heat dissipation and EMC shielding.

Military industry/security industry: Portable tactical equipment chassis, meeting the requirements of high-strength impact resistance and three-proof.

In the industrial automation industry:Small equipment control boxes, achieving wiring optimization and convenient maintenance in compact Spaces.

What is delivered is far more than just the chassis

What we deliver:

✅ heat dissipation scheme verified by thermal simulation

✅ a structurally optimized strong skeleton

✅ cost savings based on manufacturability design

✅ engineering partners who can discuss technical details at any time

Let’s start by discussing your specific challenge. There is always a professional chassis manufacturing engineer on standby, ready to assist you.We provide a solid guarantee for every chassis processing requirement of yours.

PS: If you need consultation or a solution, please feel free to contact us immediately