How important is a complete system of precision metal manufacturing equipment?

Why is a complete equipment system so crucial?

Since its establishment in 1999, we have always firmly believed that “equipment is the first line of defense for quality.” Having been deeply engaged in the field of precision metal manufacturing for many years, we have now built a full-process intelligent equipment matrix covering stamping, processing, cutting, inspection, and surface treatment.It is also a solid guarantee for achieving precision manufacturing.

PS: Understand our device matrix in detail

The hard power of precision metal manufacturing

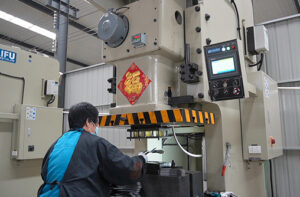

Core stamping capability

The core of the production workshop includes 38 stamping machines, ranging from 80 tons to 400 tons. From light fasteners to complex-structured heavy-metal sheets, all can be rapidly formed by stamping. All-weather automated operation, with a daily output of over 50,000 pieces, ensuring on-time delivery.

High-precision processing cluster

In response to the demand for high-precision, complex parts, five-axis machining centers, vertical machining centers, and 6-kilowatt laser cutting machines work in coordination. Four sets of laser marking machines and two sets of coordinate measuring mechanisms have established a dual-quality inspection system to maintain accuracy to 0.01 millimeters stably.

Integrated manufacturing system

With over a hundred types of metal materials in reserve, equipped with a complete set of processing equipment, including drilling, bending, and welding, as well as dedicated casting equipment, a full integrated process system has been formed.

Professional surface treatment

Two surface treatment production lines, through processes such as spraying, electroplating, and oxidation, not only enhance the appearance quality of parts, but also form a solid protective layer on the surface, achieving “both internal and external improvement”.

Service guarantee: Efficient, professional, and reliable

Systematic services ensure the smooth progress of your project:

✅An 8-hour rapid response mechanism and free sample service.

✅Provides professional design optimization support to help improve performance and reduce costs.

✅The entire process operates under an ISO 9001:2015-certified quality system and provides authoritative test reports.

PS: Learn more about how we can empower your project

Professional team and successful experience

Our professional team of 120 employees (including 19 senior engineers) works in tandem with this advanced equipment to customize over 70,000 types of parts for more than 3,000 enterprises in over 100 countries worldwide.

PS: Check out more success stories

Your metal manufacturing partner

We offer an integrated solution of equipment, technology, and service. Whether it’s simple parts or complex components, it becomes your most reliable manufacturing support.

Contact us immediately to obtain a dedicated solution for your project.