Metal Clip

We can offer you a full range of fixture products. We particularly focus on structural design and material performance to ensure reliable clamping and a long service life under various working conditions

One-stop service supply

We can customize metal clips of various materials, sizes, thicknesses, and styles. You need to hand over your requirements or drawings to us. Our professional team can provide you with one-stop, full-process services from design to finished products. Moreover, we can produce individual samples to your requirements within 12 hours and ship them to you so that you can verify the quality of our products firsthand.

Our metal customization business has been serving multiple core industries, including aerospace, medical and healthcare, automotive manufacturing, industrial equipment, and agricultural machinery.

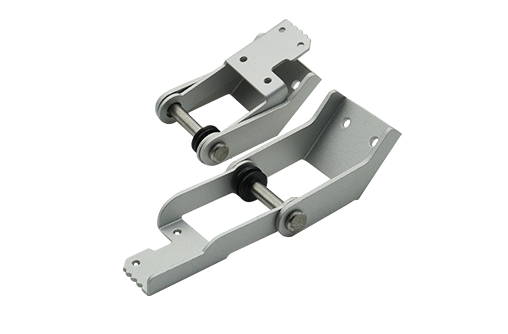

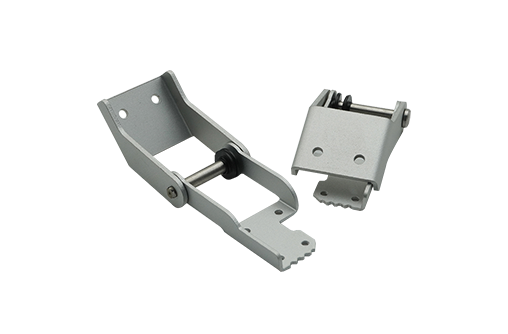

Project Cases: Metal Clip

This is a metal hinge/rotating shaft connection piece, mainly used in equipment that requires rotation and opening and closing functions, such as industrial cabinets, tool cabinets, and the connection of door bodies or components of automated equipment, to achieve flexible rotation and positioning of components. Its production process mainly includes the following links:

1. Material preparation: Select high-strength carbon steel or stainless steel plates to ensure strength and corrosion resistance. Cut the raw materials according to the dimensions of the parts.

2. Stamping forming: The main body, shaft sleeve, and other structures of the hinge are processed through stamping technology to ensure the dimensional accuracy of each component.

3. Turning processing: The rotating shaft part is turned to ensure its roundness and surface finish, guaranteeing smooth rotation.

4. Welding and assembly: Weld the stamped part to the rotating shaft as a whole, ensuring a firm weld with no false welds.

5. Surface treatment: Electroplating or painting treatment is carried out to enhance rust resistance and improve the appearance and texture.

6. Quality Inspection: Test the rotational flexibility, load-bearing capacity, and structural stability of the hinges to ensure they meet the usage requirements.

7. Packaging and Warehousing: Clean and anti-rust treat qualified products (such as applying anti-rust oil), use anti-static and anti-collision packaging (such as wrapping with pearl cotton), and sort and store them by model and batch.

Before the bulk order is confirmed, we will produce a sample within 12 hours according to your requirements and send it to you. Only after your confirmation will we start mass production.

We understand the importance of completing projects on time. For this reason, relying on automated machines, we have achieved round-the-clock automated production, with a daily output of over 9,000. We can supply goods stably at any time and strictly adhere to the delivery date, providing a solid guarantee for your needs.

NEXT: Metal Frame